Technical

Application Overview

Eldorado Stone® veneer and Hard as Rocks Application System is a BRANZ appraised simulated stone veneer cladding system designed to imitate the look of natural stone.

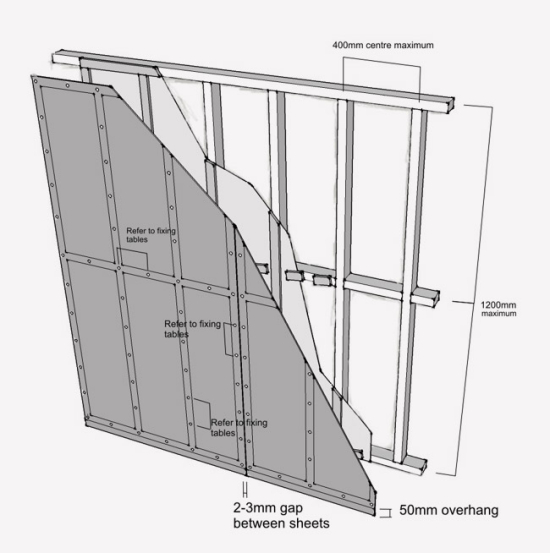

The materials used in the manufacture of Eldorado Stone veneer are lightweight aggregates, Portland cement and iron oxide pigments that are cast to mimic different styles of stone. The weight of the cladding system in total does not exceed 80kg/m2. Hard as Rocks New Zealand's installation procedure of this stone veneer cladding is generally over conventional timber framing with studs at not more than 400 mm centres, a nominal 20mm drained and ventilated cavity and a fibre-cement backing sheet sealed with a proprietary moisture resistant coating. Proprietary stainless steel tags are used as a mechanical fixing between the timber framing and the mortar/stone veneer. This cast stone veneer and its installation system can be used on domestic and light commercial buildings where domestic construction techniques are used as well as solid construction buildings as detailed below.

Stone Weight: Depending on profile, average 48kg/m2

Thickness: Depending on profile, ranges from 30 - 60mm, average 50mm

Thermal Resistance: R Factor = 0.6, varies with thickness

Combustion: Zero flame spread, zero fuel contributed and zero smoke developed

SCOPE OF USE

No substitutions are permitted for Eldorado Stone Veneer & Hard as Rocks Application System.The Eldorado Stone™ veneer and Hard as Rocks Application System has been appraised as an external wall cladding system for buildings within the following scope:

- the scope limitations of NZBC Acceptable Solution E2/AS1, Paragraph 1.1; and,

- constructed with timber framing complying with the NZBC; and,

- with a risk score of 0-20, calculated in accordance with NZBC Acceptable Solution E2/AS1, Table 2; and,

- situated in NZS 3604 Wind Zones up to, and including, Extra High.

The Eldorado Stone™ veneer and Hard as Rocks Application System has also been appraised for weather tightness and structural wind loading when used as an external wall cladding for buildings within the following scope:

- the scope limitations of NZBC Acceptable Solution E2/AS1, Paragraph 1.1 with regard to floor area and building height; and

- constructed with timber complying with the NZBC; and,

- situated in specific design wind pressures up to a maximum design differential ultimate limit state (ULS) of 2.5 kPa.

The Eldorado Stone™ veneer and Hard as Rocks Application System must only be installed on vertical surfaces (except for sills which must have a minimum 10º slope and be waterproofed in accordance with the Technical Literature).

The system is appraised for use with aluminium window and door joinery that is installed with vertical jambs and horizontal heads and sills. (The Appraisal of the Eldorado Stone™ veneer and Hard as Rocks Application System relies on the joinery meeting the requirements of NZS 4211 for the relevant Wind Zone or design wind pressure.)

SUBSTRATES

Fibre cement board

The most common and cost-effective form of application is over an approved fibre cement board substrate. We use and recommend BGC Stonesheet 7.5mm and 9mm sheets. Refer to the manufacturers specifications for all sheet cutting, layout and fixing requirements

Builder Requirements

The builder is to supply and install the fibre cement board, all relevant watertight flashings, sealant between the sheet joints and sealing around joinery.

Installation of the stone veneer and the stone veneer accessories supplied by Hard as Rocks Ltd and approved installers must be carried out only by Hard as Rocks Ltd licensed applicators.

Diagram: Batten and Fibre Cement board set-out

HARD AS ROCKS TAG SPACING

|

Tag Spacing |

Up to 3m high |

Above 3m |

|---|---|---|

|

Wind zones Low, medium and High and Earthquake Zone 1 and 2 |

250mm |

200mm |

|

Wind zones Very high, and Earthquake zones 3 and 4 (use of 9mm stonesheet required) |

200mm |

120mm |

Note: The maximum horizontal tag spacing to studs is 400mm

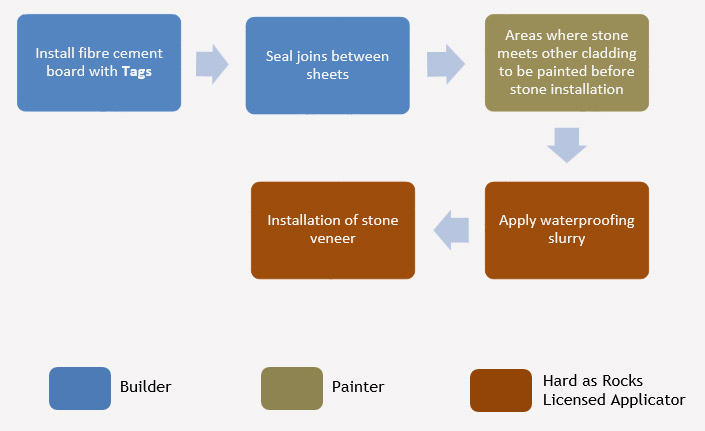

Building process

Other substrates

Concrete Masonry/Brickwork or Concrete Panels

The surface must be totally free of oil, grease, paint, curing compounds, sealers, mould release agents, dust or other loose contaminating materials. If any of these materials are present the surface must be cleaned back to the original surface by sandblasting, water blasting, acid etching or wire brushing.

Prior to stone application the surface must be waterproofed using a waterproofing slurry which is brushed or rolled on to a depth of not more than 2mm.

RESPONSIBILITIES

Building designers are responsible for all components of the building and substrate design, to comply with NZBC, and for the incorporation of the Hard as Rocks Application System into their design in accordance with the instructions of Hard as Rocks technical literature.

Builders are responsible for the supply and installation of the fibre cement board with Hard as Rocks Tags, all relevant watertight flashings, sealant between the sheet joints and sealing around joinery. All workmanship and installation of the substrate is to comply with Hard as Rocks Technical Literature and the NZBC.

Hard as Rocks Applicators are responsible for the quality of Eldorado Stone® veneer and its installation system. Installation of the stone veneer must be carried out only by Hard as Rocks licensed applicators.

Building owners are responsible for the maintenance of Eldorado Stone™ veneer and Hard as Rocks Application System in accordance with the instructions of Hard as Rocks literature.

Every 6 months the stone surface should be cleaned from dirt and grime and organic growth. To clean dirt or other particles from the stone, use a granulated type detergent mixed with water and a soft bristle brush.

If efflorescence occurs, as it does with most masonry products, it is usually caused by moisture migration through the masonry substrate when the stone is saturated. Once the moisture is on the masonry surface, it evaporates, depositing the dissolved salts in the form of efflorescence. The efflorescence will disappear gradually with time. To clean the efflorescence right away, scrub the surface with a soft bristle brush and a solution of 1 part white household vinegar mixed with 5 parts water. Wash down with clean water afterwards.